Often, the hose gets too wide, and it becomes tough to work with it. Though there may be the availability of a second hose but without proper fitting, it is absolutely of no use.

And proper fitting can only be the hydraulic hose fittings of the best quality. A hydraulic hose puts the water distribution and its pressure to move any part of the machinery into work.

These items can help in transmitting the hydraulic power to a separate device. Even the type of hydraulic hose fittings solely depends on the source of the connection and the supply.

Variety Shapes and Dimensions Available

Various kinds of hydraulic hose fittings are available in the market with varied shapes to fit the requirement. It can be of an O-ring shape. The flare fewer ones, elbow, flanges, pipe, and even face seal. The responsibility of hose settings and fixing its standards for the machinery lies in the hands of the SAE or Society of Automated Engineers.

To discuss the various kinds of hydraulic hose fittings will give detailed knowledge on the multiple styles and their usage pattern. First, the O-ring fitting where the symbolic “o” binds many threads connected with the hose pipes to have a stronger grip.

The fitting can be either a female or a male with a face seal with a flange fitting. Pressure handling in the case of an O-ring hydraulic hose fitting can be 2500 to approximately 3000 psi.

On the other hand, the flareless fittings have much less activity in tube preparation and can restrain a pressure of 3000 psi. The main advantage of this fitting is that it has a ferrule body that compresses itself and tightens into a nut to be fitted on.

Elbow Hydraulic Hose Fittings

These types of hose fittings come in several sizes. There are 90 degrees, 37 degrees, and 45 degrees for both male and female connections. As evident from the name, this hydraulic hose fitting style is where both ends are connected with the hose but at the specified angle.

These fittings are mainly used in plumbing applications where the male fitting is inserted in the female fitting to have an ideal connection. Flanges are the specified fittings for a larger tube size of more than 1 inch. The setting of these fittings needs large wrenches and high-rated tools, and even torque power to have a complete setup.

The best qualities are available in the market, with lighter ones created of carbon steel and the heavier ones of stainless steel. However, the guarantee of every manufactured product lies in the f.pact that there would be no leak in the liquid passage to the connected channel.

While purchasing these items, it is important to know the product’s authenticity to make it a worthy investment. It would help if you always fetched the guarantee, and you should use only branded company material.

The availability of these items is much wider, with the local hardware stores having a huge stock and the online suppliers giving discounts on the models displayed in their catalogs.

Research on the internet on hydraulic hose fittings will open a gateway of information to check the branded company’s models to fit a particular requirement.

Hydraulic Hose Assembly Made Easy

It is a big question to every user of any hydraulic hose assembly: how much are these assemblies’ longevity. Previously there were no answers to this. There were no fixed time parameters after which a user may understand that the life of the hydraulic hose assembly is ending, and it’s time to change the same.

Neither from the manufacturer side was any indication to say that it needs replacement. But the scenario has changed in the present day. Today there is a time limit, and there are visible indications by which you can determine the ending time.

It is wrong to use old and worn-out hydraulic hose assembly as it may turn more damaging, causing greater loss. The SAE or the Society for Automotive Engineers clearly says that a bulk rubber hose does have a life not more than ten years calculated from the day it was manufactured.

Usually, the manufacturing date remains imprinted on the lay line of the hose, checking which you may calculate the age of the hose. If the result comes nearly to ten years, then be assured it’s time for a replacement.

Also, purchasing a fresh new hydraulic hose assembly is much better than cleaning up the mess created by a broken one.

There is some prevention that you can do, which will help identify the aging and measure the correct stage of the assembly in the long run.

You may execute an inspection of the hydraulic hose assembly at a particular interval of say 30 days to understand the well functioning of the equipment, and a necessary replacement of every two years may be a good measure taken.

It has always been seen that most of the blown hoses are due to exposure to external equipment and damage. There may be abrasion, kinking, or corrosion which may reduce the life of the assemblies and which can be easily figured out by just a look at it.

Keeping log maintenance of the hosepipe inspection and its feedback may be a good way of identifying its performance. There is a critical hydraulic hose assembly that needs special care and special attention.

The basic reason for that is they may cause more damage, and that is why it is necessary to be very careful about their performance. You should replace it much earlier than the others because of the same reason.

The critical hydraulic hose assembly usually remains nearer to the operator and in critical positions. As a result, the damage caused by their breakdown is also much more than the usual assemblies.

Few sure signs of replacement are the leaking points, the loose threads, abrasion, or exposed wire. It should not be neglected as soon as the same is seen, and replacement should be done immediately.

Rust corrosion damages every metal from inside, and before it is known, huge damage can occur, which may be more costly than the price of a new hose.

However, a new hydraulic hose assembly costs are not much, and you can easily fetch it from local hardware outlets at affordable prices. It is of various designs and multiple metals, so it is important to specify the requirement. You may fetch a piece of more detailed knowledge on the types of hydraulic hose assembly from the online resources.

High-Pressure Fittings – Sizing Made Easy

High-pressure fittings are the most important engineering tool in today’s market, where high-end machinery is used at every level.

There are multiple high-pressure fittings: high-pressure hydraulic fittings, high-pressure pipe fittings, larger pressure hose fittings, and high-pressure fittings machinery. There can also be valve fittings, high-pressure tee, high-pressure swivel, the 90’s as well as straight-line adapters.

The hydraulic hose is a renowned and acclaimed tool that serves the basic purpose of transmitting force in hydraulic machines. It is essentially a variety of high-pressure fitting that carries fluid and power and transmits them to others.

It was first in the year 1940 when you produced the same. It is an essential tool used by various industries and even in household premises in multiple utilization.

The hydraulic hose is famous for its quality of high-pressure fittings. There are many types of hydraulic hoses which are found today to solve the purpose of high-pressure fittings. They are articulated, corrugated, coiled, reinforced, and multi-element hoses.

The basic structure of the hydraulic is meant to be ideal high-pressure fittings. It has an essentially inner tube that is much flexible and compatible to carry the fluids consisting of spiral-bound wire and textile yarn, with multiple sheaths of the braided wire, and an outer layer giving protection from climate changes along with being abrasion and much oil resistant.

The design of the hydraulic hose stands for its size, application, temperature materials, ends, pressure, and delivery.

However, since these are high-pressure fittings, it is quite natural that their life span is not long since they have to undergo much greater force every time. Hydraulic hoses have the power to transfer a minimal pressure transmitting it to hundreds of tons while in its output.

They have the ability to create low-speed torque and manage the speed and velocity of the machines with supreme accuracy. They have the inbuilt nature of generating and controlling the high pressure, making them highly demanded fittings for every industry.

The high-pressure fittings have a wide range of suppliers both in the online and hardware markets. It is essential to have branded company products in this genre because high-rated machinery can turn supremely damaging if the product is of foul make.

That’s the reason why the trusted and reliable brands are always preferable. They have been dealing with the industry for a long, and they are dependable for making high-quality pressure fittings that can go up to 60,000 psi.

It depends from company to company, but most of them have a larger and wider range of applications in each segment, be it hose settings or the pipe fittings, and the pressure range for each equipment also varies a lot.

There is medium pressure equipment with the highest level of 20,000 psi, but it entirely depends on the purchaser he wants to purchase.

There are catalogs available with details of every fitting, which makes it more advantageous for the purchaser to select the ideal high-pressure fittings for his machinery. The prices from the online stores are much controlled as they have special offers which can bring the price down by a few dollars from the market price.

Hydraulic Pipe Fittings Explained

Hydraulic pipe fittings are important engineering tools that are high utility when the standard-sized hydraulic tubes are not working. These are mostly used in low pressure connected by the threaded connections and also by welds. It has the basic work of transmitting the hydraulic power, and without proper hydraulic pipe fittings, it is impossible to do the same.

There are multiple varieties of hydraulic pipe fittings available in the market. The brands have taken full control of the market with quality end products for the large industries and smaller requirements.

The hydraulic pipe fittings have paved the path for newer designs that can be simply assembled, making it absolutely user-friendly for every customer, easy and simple maintenance process, and eliminating any chances of leakage.

There are multiple styles like the o ring fittings or the flare type fittings and the flanges, which can be used according to the requirement.

The availability of the hydraulic pipe fittings is not much difficult; however, it is always advisable to have branded products for the simple reason that these products are used in transmitting power, and they are required to be much stronger and reliable.

Bad quality fittings will hamper the work, causing more damage and ruining the investment made on it. Several branded companies are serving the industry for many years with good quality products.

The local stores may have a good collection, or you may access a wider catalog with the online portals where several good companies advertise their products with details of the various fittings advertised to display a clear knowledge of the product’s various features.

You can purchase a full range of fittings from the online retailers with male stud coupling, straight coupling, elbow tee, adapter, etc.

All that is required and more equipment can be fetched by surfing several model packages. All the apparatus are double bite ferrule and with BSP(t) thread. They are true of the best quality with the facility to have detailed catalog descriptions on every model if an inquiry is sent.

The prices in the online portals are also much cheaper than the outside market of hydraulic pipe fittings. The retailers of these hydraulic pipe fittings give discounts and offer their products with advantages like free shipping, making it a more lucrative deal. The offered percentage also differs from the number of orders. More numbers will ensure a lesser price.

In most online portals, there are concepts of star suppliers and leading suppliers that are a more genuine business of the seller. While purchasing the hydraulic pipe fittings, you should also check those parameters before finalizing the deal.

Some sellers give cashback opportunities in case of a manufacturing defect. Also, there are options for a greater warranty period. Similar facilities are always profitable in the long run.

So a careful survey on the various sellers of hydraulic tube fittings will ensure a good deal and purchase worth money invested. Online purchase is always much better since the arena of the market remains the widest.

Solid Brass Garden Hose Fittings On Machined Brass Fittings

Whether you are a plant enthusiast, beginner, or novice gardener, you know and realize the importance of a good irrigation system for your garden or lawn with solid brass garden hittings.

For many, the garden hose is the essential tool that ties it all together. Therefore, making any accessories that improve the effectiveness of this tool, such as garden hose fittings, is a vital investment.

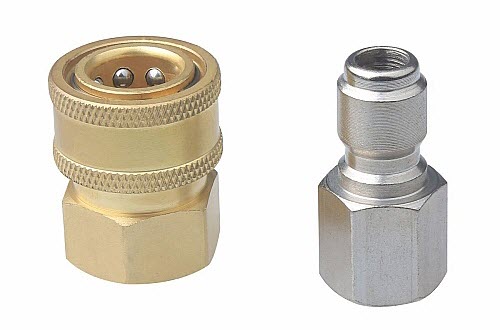

What is a garden hose fitting, and what is the advantage of buying the solid brass fitting over the machined brass fitting? The quality of the actual hose is only maximized by the strength and quality construction of the actual fitting.

A garden hose fitting is a coupling or nozzle that controls the water coming from the hose. It also controls the level of saturation experienced by your plants or lawn, and it is directly responsible for the amount of potential waste experienced.

The decision to purchase durable fittingly that resists rusting and provides great valve flow control is key to the success of your irrigation efforts.

Garden Hose Fittings

Garden hose fittings that are constructed of solid brass are an essential complement to a quality hose. They are of more high-quality construction, stronger, not prone to rusting and deformities.

On the other hand, machined brass fittings are made from thinner layers of a brass-like compound and, therefore, not as strong. They provide a less expensive alternative, but when planning your irrigation system, you must remember that you get what is paid for.

Machined brass fittings have been known to become leaky with repeated use and even deformed due to the constant water pressure. Spending a little bit more money in the beginning to purchase a solid brass coupling can actually prove more cost-effective and result in longer life of your garden hose.

How to Use It?

Brass hose fittings are very simple to use, plus it is very flexible and rugged. It won’t get damaged if you drop it or thread on it. More importantly, it doesn’t leak.

The heart of the system is the tap connector, where you need to connect it to the outside thread of the tap. There was a rubber seal with it, so you need to clean it up. Another part that locks into it is the hose connector.

To fit it to the hose, you just need to undo the collar and fit it through your hose, and then fit the end of the hose into it. With machine brass, you will notice that you can get a really tight and secure lock on the hose so it won’t pull off.

The inside of the connector is built with stainless steel ball bearings. They do the locking but don’t corrode, and they will lock themselves when they get rusty. To connect to the tap, you need to pull back on the collar, push up to the tap, and it is done.

If you want to connect 2 ends of the hose permanently, you can use a brass joiner. You can put the end cap on the hose fittings and lock them together. You will get a solid and permanent connection.

If you want to join the 2 ends of the parts quickly, you can get brass couplings that are on already with a male connector. You need to pull the ring and push the connection to one side and take the other bit of pipe and do the same. You can also disconnect them by pulling the ring back and pull them apart.

Hexagonal Swivel in Need

When purchasing this product, you should use a hexagonal swivel to reinforce the strength of the attachment to the faucet.

This directly contributes to the reduction of water waste. It also facilitates the easy transportation of the hose from one area to another without a lot of hassle and awkward maneuvering to dislodge the hose from the faucet.

As discussed, solid brass garden hose fittings are durable and actually cost-effective and can be purchased at any home improvement or hardware store or even online. The 3 famous fittings brands are Anderson, Dixon, and Nelson.

Your drip irrigation system is an important part of your garden. Make the decision that will save you money in the long run and contribute to water-saving efforts by purchasing solid brass garden hose fittings.

Hmm.. you know what? Thanks a bunch for specifying that conducting a monthly examination can ensure the longevity of our hydraulic hose. My aunt is currently planting some flowers in her backyard garden and she needs some tools to manage them. I’ll show this article to her so she’ll purchase the right items soon.

It’s amazing to learn that a hydraulic pipe fitting is an engineering tool that are highly utilized when the standard hydraulic tubes aren’t working. My dad’s on the hunt for a hydraulic hose he can use in his high-powered industrial company. I have no idea what those things are for so I’m glad this article is here to help me understand hydraulic stuff.